What We Do ?

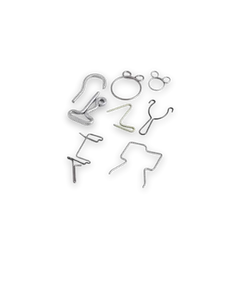

Recognized as a trusted leader in precision springs

With decades of engineering expertise, Kishor Springs has built a strong reputation for manufacturing high-performance compression, tension, torsion and customized springs tailored to exact application requirements. Backed by advanced CNC machinery, strict quality control systems and skilled technical teams, we consistently deliver products that meet demanding industry standards. Our focus on precision, durability and timely delivery enables us to support automotive, electrical, engineering, healthcare and lifestyle industries across India with confidence and reliability.

Premium Quality Springs

Every product we create is designed to help you stay consistent, stay strong.

Experienced Professionals

Our skilled engineering team ensures accuracy, consistency and reliable performance.

- Designed for performance, built to last

- Innovation that moves with you